Are you over 18 and want to see adult content?

More Annotations

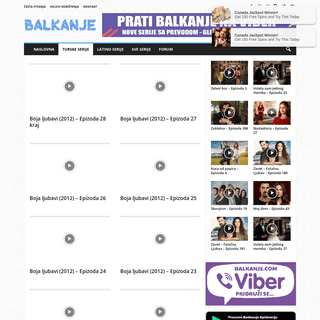

A complete backup of https://balkanje.com/turske-serije/boja-ljubavi-2012/

Are you over 18 and want to see adult content?

A complete backup of https://balkanje.com/latino-serije/otadzbina-2020/

Are you over 18 and want to see adult content?

A complete backup of https://balkanje.com/turske-serije/

Are you over 18 and want to see adult content?

A complete backup of https://balkanje.com/turske-serije/napadac-2021/

Are you over 18 and want to see adult content?

A complete backup of https://balkanje.com/izmedju-nas-epizoda-5/

Are you over 18 and want to see adult content?

A complete backup of https://balkanje.com/latino-serije/druga-zena-2002/

Are you over 18 and want to see adult content?

A complete backup of https://balkanje.com/vrtlog-zivota-epizoda-21/

Are you over 18 and want to see adult content?

A complete backup of https://balkanje.com/vrtlog-zivota-epizoda-22/

Are you over 18 and want to see adult content?

Favourite Annotations

A complete backup of discordcomics.com

Are you over 18 and want to see adult content?

A complete backup of deciphertools.com

Are you over 18 and want to see adult content?

A complete backup of farmaciasanpablo.com.mx

Are you over 18 and want to see adult content?

A complete backup of legallaworder.com

Are you over 18 and want to see adult content?

A complete backup of thefirstnews.com

Are you over 18 and want to see adult content?

A complete backup of commongroundalliance.com

Are you over 18 and want to see adult content?

A complete backup of annandalegolf.com

Are you over 18 and want to see adult content?

A complete backup of triathloncanada.com

Are you over 18 and want to see adult content?

Text

printed parts.

LEAPFROG PROFESSIONAL 3D PRINTER OVERVIEW The Leapfrog XceL takes large scale 3D printing into the next level. The XceL is one of the largest professional FDM 3D printers with capabilities to make life-size prints easily. XceL’s advanced Direct Drive Extrusion System offers limitless possibilities in terms of BOLT PRO | PROFESSIONAL 3D PRINTER | LEAPFROG 3D PRINTERS Designed for organisations, the Bolt Pro can run constantly, print with any 3D printing filament in the market and offers remote management features to ensure projects run effectively at all times. Leapfrog 3D Printers built the Bolt Pro 3D printer to give our users the optimal solution to convert their ideas into functional andtangible products.

SHORT GUIDE IN PAINTING 3D PLA MODELS Here are a few steps you should follow when painting your 3D models: 1. Cleaning up. After your print has finished clean your model and give it the final retouches it needs. You can remove tiny artefacts using an Exacto blade or Stanley knife. For removing rough surfaces from where support was attached, you can use a Dremel tool. HOW MUCH DOES IT COST TO 3D PRINT? 3D printing costs depend on the type of printing technology used. There are 3 types: SLS (Selective Laser Sintering), SLA (Stereolithography) and FDM (Fused Deposition Modeling). FDM is the cheapest technology among the three listed, and SLS is the most expensive one. You can find an affordable FDM printer from €100, while an SLS machine will FIRMWARE : LEAPFROG CUSTOMER SUPPORT CENTER Find out which firmware your machine needs by following these steps: 1) Does your Creatr have a black drag chain that guides the wires from the printing Wed, 11 Mar, 2020 at 8:50 AM. HOW TO CONFIGURE CURA This solution article will explain how to set-up the printer as a 'Custom FFF printer' in Cura. Cura is a free slicer that can be used on your computer. This tutorial is compatible with Cura 4.5 and possible newer. Step 1: Download Cura Down HOW TO CONFIGURE SIMPLIFY 3D FOR MY LEAPFROG 3D PRINTER 1. Open up Simplify 3D and go to the Help section; 2. Then simply find your printer in the list and load the configuration; 3. The moment you do this the print profiles will automatically be generated. We thank you for checking out our Leapfrog 3D Printer technical support solutions online! If you were unable to fine a solution in ourdatabase

CONFIGURATION PARAMETERS AND SCRIPTS LEAPFROG CREATR Please find below the parameters and scripts used for Leapfrog Creatr dual and Simplify3D. Starting Script G28 F1200 ; home all axes T0 ; switch to right extruder G1 Z0.2 ; raise nozzle G92 E0 ; zero extruder G1 E3 F225 ; purge nozzle T HOW TO IMPORT DOWNLOADED PRINT PROFILES INTO SIMPLIFY 3D We thank you for checking out our Leapfrog 3D Printer technical support solutions online!If you were unable to fine a solution in our database, please feel free to open a new support ticket by clicking the following link: I want to open a new support ticket. LEAPFROG 3D PRINTERS These range from prototyping parts before mass production, to producing functional parts that can demonstrate how a part will work. To help these companies, Leapfrog 3D Printers designs and produces a range of professional 3D printing solutions that aim to help our customers achieve results faster and produce the highest quality 3Dprinted parts.

LEAPFROG PROFESSIONAL 3D PRINTER OVERVIEW The Leapfrog XceL takes large scale 3D printing into the next level. The XceL is one of the largest professional FDM 3D printers with capabilities to make life-size prints easily. XceL’s advanced Direct Drive Extrusion System offers limitless possibilities in terms of BOLT PRO | PROFESSIONAL 3D PRINTER | LEAPFROG 3D PRINTERS Designed for organisations, the Bolt Pro can run constantly, print with any 3D printing filament in the market and offers remote management features to ensure projects run effectively at all times. Leapfrog 3D Printers built the Bolt Pro 3D printer to give our users the optimal solution to convert their ideas into functional andtangible products.

SHORT GUIDE IN PAINTING 3D PLA MODELS Here are a few steps you should follow when painting your 3D models: 1. Cleaning up. After your print has finished clean your model and give it the final retouches it needs. You can remove tiny artefacts using an Exacto blade or Stanley knife. For removing rough surfaces from where support was attached, you can use a Dremel tool. HOW MUCH DOES IT COST TO 3D PRINT? 3D printing costs depend on the type of printing technology used. There are 3 types: SLS (Selective Laser Sintering), SLA (Stereolithography) and FDM (Fused Deposition Modeling). FDM is the cheapest technology among the three listed, and SLS is the most expensive one. You can find an affordable FDM printer from €100, while an SLS machine will FIRMWARE : LEAPFROG CUSTOMER SUPPORT CENTER Find out which firmware your machine needs by following these steps: 1) Does your Creatr have a black drag chain that guides the wires from the printing Wed, 11 Mar, 2020 at 8:50 AM. HOW TO CONFIGURE CURA This solution article will explain how to set-up the printer as a 'Custom FFF printer' in Cura. Cura is a free slicer that can be used on your computer. This tutorial is compatible with Cura 4.5 and possible newer. Step 1: Download Cura Down HOW TO CONFIGURE SIMPLIFY 3D FOR MY LEAPFROG 3D PRINTER 1. Open up Simplify 3D and go to the Help section; 2. Then simply find your printer in the list and load the configuration; 3. The moment you do this the print profiles will automatically be generated. We thank you for checking out our Leapfrog 3D Printer technical support solutions online! If you were unable to fine a solution in ourdatabase

CONFIGURATION PARAMETERS AND SCRIPTS LEAPFROG CREATR Please find below the parameters and scripts used for Leapfrog Creatr dual and Simplify3D. Starting Script G28 F1200 ; home all axes T0 ; switch to right extruder G1 Z0.2 ; raise nozzle G92 E0 ; zero extruder G1 E3 F225 ; purge nozzle T HOW TO IMPORT DOWNLOADED PRINT PROFILES INTO SIMPLIFY 3D We thank you for checking out our Leapfrog 3D Printer technical support solutions online!If you were unable to fine a solution in our database, please feel free to open a new support ticket by clicking the following link: I want to open a new support ticket. LEAPFROG PROFESSIONAL 3D PRINTER OVERVIEW Xcel. The Leapfrog XceL takes large scale 3D printing into the next level. The XceL is one of the largest professional FDM 3D printers with capabilities to make life-size prints easily. XceL’s advanced Direct Drive Extrusion System offers limitless possibilities in terms of precision, speed and print quality. SHORT GUIDE IN PAINTING 3D PLA MODELS Here are a few steps you should follow when painting your 3D models: 1. Cleaning up. After your print has finished clean your model and give it the final retouches it needs. You can remove tiny artefacts using an Exacto blade or Stanley knife. For removing rough surfaces from where support was attached, you can use a Dremel tool. 3D PRINTING WITH POLYPROPYLENE However, Polypropylene enables new possibilities, which is the heart of 3D printing. Better hinging capabilities, better chemical resistance, and a good surface finish; these are the things that will appeal to a lot for unique users and specialized industries. And right now, our unique experience with the Leapfrog Bolt Pro 3D printer feels 3D PRINTING HYBRID FILAMENT ABS. ABS (Acrylonitrile Butadiene Styrene) is a strong popular filament that is used widely for 3D printing parts. It has strong material properties which produce parts with high impact, high-temperature resista nce. Having these qualities however does make it a little harder to print with than some other filaments, but our printers come with a heated bed that ensures the filament is INDEPENDENT DUAL EXTRUDERS IDEX – short for Independent Dual Extruders – is the 3D printing technique that allows two print heads to move independently from each other. Each head has its own nozzle and can print with the same, or different material than the other head. This technology has a number of advantages in comparison to a single head with dual extruders. SOLUTIONS : LEAPFROG CUSTOMER SUPPORT CENTER Firmware 4. Software Re-install (User Interface) Firmware Update (Motor Control Board) Creatr HS (XL) Firmware archive Creatr HS (XL) Software Update (User Interface) Creatr HS (XL) Repair Instructions 39. Print Head Stops Mid-Print: Checking the Thermistor and Ribbon Cable - Creatr HS. Replacement head fans. How to Install, Repair, orReplace

FIRMWARE: WHICH VERSION DO I NEED FOR MY CREATR (XL Modified on: Wed, 11 Mar, 2020 at 8:50 AM. Find out which firmware your machine needs by following these steps: 1) Does your Creatr have a black drag chain that guides the wires from the printing carriage to the back of the machine? Yes: Go to step 2 No: Go to step 3. 2) Measure the diameter of the machine's back Z-axis pulley like shown inthe

USER MANUAL

Sorry we couldn't be helpful. Help us improve this article with yourfeedback.

FIRMWARE: HOW TO UPLOAD TO CREATR (XL)? : LEAPFROG Setting Up Arduino. 1) Start by connecting the printer to the computer through USB. 2) Then open the Arduino software. 3) Next, you will have to choose the correct Serial Port number for the printer. This COM port varies depend on the OS; t he correct number for the serial port is the highest number you find available. So if you have for example COM 1 and COM 45 the correct one is COM 45. SIMPLIFY3D PRINT SETTINGS TABS EXPLAINED BY SIMPLIFY3D'S Applies to Simplify3D users looking to learn more about the settings in the .FFF Settings window. - Very Useful! The following links are from Simplify3D's Customer Support Forum where one of their experts goes into detail explaining the sett LEAPFROG 3D PRINTERS These range from prototyping parts before mass production, to producing functional parts that can demonstrate how a part will work. To help these companies, Leapfrog 3D Printers designs and produces a range of professional 3D printing solutions that aim to help our customers achieve results faster and produce the highest quality 3Dprinted parts.

LEAPFROG PROFESSIONAL 3D PRINTER OVERVIEW The Leapfrog XceL takes large scale 3D printing into the next level. The XceL is one of the largest professional FDM 3D printers with capabilities to make life-size prints easily. XceL’s advanced Direct Drive Extrusion System offers limitless possibilities in terms of BOLT PRO | PROFESSIONAL 3D PRINTER | LEAPFROG 3D PRINTERS Designed for organisations, the Bolt Pro can run constantly, print with any 3D printing filament in the market and offers remote management features to ensure projects run effectively at all times. Leapfrog 3D Printers built the Bolt Pro 3D printer to give our users the optimal solution to convert their ideas into functional andtangible products.

SHORT GUIDE IN PAINTING 3D PLA MODELS Here are a few steps you should follow when painting your 3D models: 1. Cleaning up. After your print has finished clean your model and give it the final retouches it needs. You can remove tiny artefacts using an Exacto blade or Stanley knife. For removing rough surfaces from where support was attached, you can use a Dremel tool. HOW MUCH DOES IT COST TO 3D PRINT? 3D printing costs depend on the type of printing technology used. There are 3 types: SLS (Selective Laser Sintering), SLA (Stereolithography) and FDM (Fused Deposition Modeling). FDM is the cheapest technology among the three listed, and SLS is the most expensive one. You can find an affordable FDM printer from €100, while an SLS machine will FIRMWARE : LEAPFROG CUSTOMER SUPPORT CENTER Find out which firmware your machine needs by following these steps: 1) Does your Creatr have a black drag chain that guides the wires from the printing Wed, 11 Mar, 2020 at 8:50 AM. HOW TO CONFIGURE CURA This solution article will explain how to set-up the printer as a 'Custom FFF printer' in Cura. Cura is a free slicer that can be used on your computer. This tutorial is compatible with Cura 4.5 and possible newer. Step 1: Download Cura Down HOW TO CONFIGURE SIMPLIFY 3D FOR MY LEAPFROG 3D PRINTER 1. Open up Simplify 3D and go to the Help section; 2. Then simply find your printer in the list and load the configuration; 3. The moment you do this the print profiles will automatically be generated. We thank you for checking out our Leapfrog 3D Printer technical support solutions online! If you were unable to fine a solution in ourdatabase

CONFIGURATION PARAMETERS AND SCRIPTS LEAPFROG CREATR Please find below the parameters and scripts used for Leapfrog Creatr dual and Simplify3D. Starting Script G28 F1200 ; home all axes T0 ; switch to right extruder G1 Z0.2 ; raise nozzle G92 E0 ; zero extruder G1 E3 F225 ; purge nozzle T HOW TO IMPORT DOWNLOADED PRINT PROFILES INTO SIMPLIFY 3D We thank you for checking out our Leapfrog 3D Printer technical support solutions online!If you were unable to fine a solution in our database, please feel free to open a new support ticket by clicking the following link: I want to open a new support ticket. LEAPFROG 3D PRINTERS These range from prototyping parts before mass production, to producing functional parts that can demonstrate how a part will work. To help these companies, Leapfrog 3D Printers designs and produces a range of professional 3D printing solutions that aim to help our customers achieve results faster and produce the highest quality 3Dprinted parts.

LEAPFROG PROFESSIONAL 3D PRINTER OVERVIEW The Leapfrog XceL takes large scale 3D printing into the next level. The XceL is one of the largest professional FDM 3D printers with capabilities to make life-size prints easily. XceL’s advanced Direct Drive Extrusion System offers limitless possibilities in terms of BOLT PRO | PROFESSIONAL 3D PRINTER | LEAPFROG 3D PRINTERS Designed for organisations, the Bolt Pro can run constantly, print with any 3D printing filament in the market and offers remote management features to ensure projects run effectively at all times. Leapfrog 3D Printers built the Bolt Pro 3D printer to give our users the optimal solution to convert their ideas into functional andtangible products.

SHORT GUIDE IN PAINTING 3D PLA MODELS Here are a few steps you should follow when painting your 3D models: 1. Cleaning up. After your print has finished clean your model and give it the final retouches it needs. You can remove tiny artefacts using an Exacto blade or Stanley knife. For removing rough surfaces from where support was attached, you can use a Dremel tool. HOW MUCH DOES IT COST TO 3D PRINT? 3D printing costs depend on the type of printing technology used. There are 3 types: SLS (Selective Laser Sintering), SLA (Stereolithography) and FDM (Fused Deposition Modeling). FDM is the cheapest technology among the three listed, and SLS is the most expensive one. You can find an affordable FDM printer from €100, while an SLS machine will FIRMWARE : LEAPFROG CUSTOMER SUPPORT CENTER Find out which firmware your machine needs by following these steps: 1) Does your Creatr have a black drag chain that guides the wires from the printing Wed, 11 Mar, 2020 at 8:50 AM. HOW TO CONFIGURE CURA This solution article will explain how to set-up the printer as a 'Custom FFF printer' in Cura. Cura is a free slicer that can be used on your computer. This tutorial is compatible with Cura 4.5 and possible newer. Step 1: Download Cura Down HOW TO CONFIGURE SIMPLIFY 3D FOR MY LEAPFROG 3D PRINTER 1. Open up Simplify 3D and go to the Help section; 2. Then simply find your printer in the list and load the configuration; 3. The moment you do this the print profiles will automatically be generated. We thank you for checking out our Leapfrog 3D Printer technical support solutions online! If you were unable to fine a solution in ourdatabase

CONFIGURATION PARAMETERS AND SCRIPTS LEAPFROG CREATR Please find below the parameters and scripts used for Leapfrog Creatr dual and Simplify3D. Starting Script G28 F1200 ; home all axes T0 ; switch to right extruder G1 Z0.2 ; raise nozzle G92 E0 ; zero extruder G1 E3 F225 ; purge nozzle T HOW TO IMPORT DOWNLOADED PRINT PROFILES INTO SIMPLIFY 3D We thank you for checking out our Leapfrog 3D Printer technical support solutions online!If you were unable to fine a solution in our database, please feel free to open a new support ticket by clicking the following link: I want to open a new support ticket. LEAPFROG PROFESSIONAL 3D PRINTER OVERVIEW Xcel. The Leapfrog XceL takes large scale 3D printing into the next level. The XceL is one of the largest professional FDM 3D printers with capabilities to make life-size prints easily. XceL’s advanced Direct Drive Extrusion System offers limitless possibilities in terms of precision, speed and print quality. SHORT GUIDE IN PAINTING 3D PLA MODELS Here are a few steps you should follow when painting your 3D models: 1. Cleaning up. After your print has finished clean your model and give it the final retouches it needs. You can remove tiny artefacts using an Exacto blade or Stanley knife. For removing rough surfaces from where support was attached, you can use a Dremel tool. 3D PRINTING WITH POLYPROPYLENE However, Polypropylene enables new possibilities, which is the heart of 3D printing. Better hinging capabilities, better chemical resistance, and a good surface finish; these are the things that will appeal to a lot for unique users and specialized industries. And right now, our unique experience with the Leapfrog Bolt Pro 3D printer feels 3D PRINTING HYBRID FILAMENT ABS. ABS (Acrylonitrile Butadiene Styrene) is a strong popular filament that is used widely for 3D printing parts. It has strong material properties which produce parts with high impact, high-temperature resista nce. Having these qualities however does make it a little harder to print with than some other filaments, but our printers come with a heated bed that ensures the filament is INDEPENDENT DUAL EXTRUDERS IDEX – short for Independent Dual Extruders – is the 3D printing technique that allows two print heads to move independently from each other. Each head has its own nozzle and can print with the same, or different material than the other head. This technology has a number of advantages in comparison to a single head with dual extruders. SOLUTIONS : LEAPFROG CUSTOMER SUPPORT CENTER Firmware 4. Software Re-install (User Interface) Firmware Update (Motor Control Board) Creatr HS (XL) Firmware archive Creatr HS (XL) Software Update (User Interface) Creatr HS (XL) Repair Instructions 39. Print Head Stops Mid-Print: Checking the Thermistor and Ribbon Cable - Creatr HS. Replacement head fans. How to Install, Repair, orReplace

FIRMWARE: WHICH VERSION DO I NEED FOR MY CREATR (XL Modified on: Wed, 11 Mar, 2020 at 8:50 AM. Find out which firmware your machine needs by following these steps: 1) Does your Creatr have a black drag chain that guides the wires from the printing carriage to the back of the machine? Yes: Go to step 2 No: Go to step 3. 2) Measure the diameter of the machine's back Z-axis pulley like shown inthe

USER MANUAL

Sorry we couldn't be helpful. Help us improve this article with yourfeedback.

FIRMWARE: HOW TO UPLOAD TO CREATR (XL)? : LEAPFROG Setting Up Arduino. 1) Start by connecting the printer to the computer through USB. 2) Then open the Arduino software. 3) Next, you will have to choose the correct Serial Port number for the printer. This COM port varies depend on the OS; t he correct number for the serial port is the highest number you find available. So if you have for example COM 1 and COM 45 the correct one is COM 45. SIMPLIFY3D PRINT SETTINGS TABS EXPLAINED BY SIMPLIFY3D'S Applies to Simplify3D users looking to learn more about the settings in the .FFF Settings window. - Very Useful! The following links are from Simplify3D's Customer Support Forum where one of their experts goes into detail explaining the settOpen menu

* HOME

* PRODUCTS

* 3D PRINTERS

*

BOLT PRO

*

XCEL

*

XEED 2.0

* FILAMENTS

* EXTRAS

*

ADD-ONS

*

SPARE PARTS

* REVIEWS

* TESTIMONIALS

*

BOLT PRO - KLM

*

KLM AND LEAPFROG: A SUCCESS STORY*

WHAT IS VOLKSWAGEN USING THE LEAPFROG 3D PRINTERS FOR?* REVIEWS

*

3DPRINTING.COM – BOLT REVIEW*

3DPI: REVIEW ON PROFESSIONAL 3D PRINTER – BOLT PRO*

3DPRINTR.COM: REVIEWING THE UNIQUE FEATURES OF BOLT* CUSTOMERS

* KNOWLEDGE

* 3D COURSES

* APPLICATIONS

* GUIDES

* BLOG

* COMPANY

* JOBS

* NEWS

* EVENTS

* ABOUT US

* CONTACT US

* RESELLERS

* SUPPORT

Refurbished Bolt Pro E3D hot ends BuildTak beds IGUS cables V3 Touch Screen 12 month warranty €4000 Discover our BOLT PRO 3DPRINTER

TESTIMONIALS

VIDEO TESTIMONIAL: FUJITSU AIMING HIGH WITH THE BOLT PRO WHY DID WE CHOOSE THE BOLT PRO > ‘We chose Leapfrog instead of other brands for two reasons. > Firstly, because it has an open environment that allowed us to use a > variety of materials rather than limiting to just one. Secondly, > because it has certain features that we didn’t find in other > machines of its range.’*

WE USE THE BOLT PRO TO CREATE DESIGNS THAT WERE MADE WITH TRADITIONAL TECHNOLOGY LIKE MILLING.*

CREATING TOOLING FOR THE PRODUCTION LINE.*

3D PRINTING REQUIRES FEWER PARTS, THE COST IS LESS AND ITS MUCH FASTER, ADDITIONALLY IT HAS THE FLEXIBILITY TO TEST MULTIPLE CONCEPTS WITHOUT INCREASING COSTS TO THE PRODUCTION LINES, WHICH IS IMPORTANT.*

THE RETURN ON INVESTMENT HAS BEEN VERY FAST, IN ABOUT 6 MONTHS.*

WE HAVE NOTICED THAT OUR FLEXIBILITY AND OUR SPEED TO TRY NEW CONCEPTS HAS INCREASED EXPONENTIALLY. _LUIS DE LA JARA, COORDINATOR MECHANICAL DESIGNERS_ _AUTOMOTIVE ENGINEERING DEPARTMENT FUJISTU SPAIN_ SEE VIDEO TESTIMONIAL KLM AND LEAPFROG: A SUCCESS STORY WHY DID WE CHOOSE THE BOLT PRO 3D PRINTER?*

WE CHOSE THE BOLT PRO BECAUSE OF ITS RIGIDITY AND THE OPTION TO PRINT TWO PARTS SIMULTANEOUSLY WITH THE TWO HEADS. ANOTHER ADVANTAGE IS THE ABILITY TO PRINT HIGH-TEMPERATURE MATERIALS. WE HAVE TWO BOLT PRO PRINTERS IN OUR ENGINEERING & MAINTENANCE DEPARTMENT:*

WE ALSO PRINT PROTOTYPES OF SMALL AIRCRAFT CABIN PARTS. THESE PROTOTYPES ARE ACTUALLY TESTED ON BOARD BY CABIN CREW. FINAL DESIGNS ARE MASS PRODUCED BY INJECTION MOLDING FROM CERTIFIED MATERIALS.*

THE DIMENSIONAL ACCURACY OF THE PRINTS IS VERY GOOD. > ‘_I CERTAINLY RECOMMEND THE BOLT PRO BECAUSE OF ITS RIGIDITY, ITS > LARGE PRINT BED AND THE TWO PRINT HEADS WHICH DOUBLE THE PRINT SPEED > ONCE MORE SIMILAR PARTS ARE NEEDED. I THINK THE LEAPFROG BOLT PRO IS > VERY SUITABLE FOR ENGINEERING IN PROTOTYPING AND IT CAN EVEN PRODUCE > A SMALL SERIES OF PLASTIC PARTS’_. _MAARTEN OTTEVANGER, PROCESS ENGINEER_ _ KLM Engineering & Maintenance_ WHAT IS VOLKSWAGEN USING THE LEAPFROG 3D PRINTERS FOR? REASONS WHY WE CHOSE THE LEAPFROG BOLT PRO*

THE BOLT WAS ANALYZED AS THE BEST MACHINE FOR PRINTING FLEXIBLE MATERIALS DUE TO THE DIRECT DRIVE SYSTEM*

RELATIVELY LARGE BUILD VOLUME, ESPECIALLY CONSIDERING SIZE VS. COST*

2 INDEPENDENT DUAL EXTRUDER SYSTEM IDEX SINCE WE ASSEMBLE CARS FOR BOTH LEFT AND RIGHT DRIVING SIDES, SO THIS HELPS A LOT FOR BUILDINGMIRROR PARTS

*

RELIABLE – ALTHOUGH WE HAD OUR STARTUP ISSUES WITH THIS UNIT, SUPPORT WAS GOOD AND WE MANAGED TO CORRECT ISSUES. WE BELIEVE THE LEAPFROG BOLT PRO IS A VERY RELIABLE MACHINE FOR THE WAY WE USE THISEQUIPMENT.

WHAT ARE WE USING THE BOLT PRO FOR?*

SERIAL TOOL PRODUCTION IN OUR PRODUCTION LINE*

WE HAVE INSERTED 3D PRINTING INTO OUR ASSEMBLY PROCESS THROUGHOUT THE WHOLE PRODUCTION LINE Summarizing, our engineers using the Leapfrog 3D printers are more than thrilled about the results and potential the Leapfrog printers have; your 3D printers are better from numerous points of view (PRINTING MATERIALS, IDEX, BUILD VOLUME ETC). At the same time, we also see room for improvements and are happy to share feedback for further development ideas. 5 REASONS WHY ROLLS ROYCE CHOSE LEAPFROG’S 3D PRINTERS THE FEATURES THAT MADE THE BOLT PRO IDEAL FOR ROLLS ROYCE Rolls Royce was in the market for a new 3D printing solution so as to be able to expand their internal rapid prototyping capabilities. They looked at various machines We looked at a range of machines from cheap Chinese hobbyist machines all the way up to eye-watering expensive liquid polymer based printers but our deciding criteria were:*

DUAL EXTRUSION – SOLUBLE SUPPORT MATERIAL IS VERY IMPORTANT FOR THE TYPES OF MODELS WE WILL BE PRINTING, OFTEN INVOLVING LARGE OVERHANGS AND INTRICATE INTERNAL FEATURES.*

FULL ENCLOSURE – TWO REASONS FOR THIS, FIRST BEING TO STOP THE CURIOUS/IGNORANT INJURING THEMSELVES AND THE SECOND IS TO PROVIDE AN ENVIRONMENT CONDUCIVE TO MAXIMISING PRINT QUALITY. THE ONLY AREA WHERE THE LEAPFROG BOLT PRO COULD BE BETTER IS A HEATED ENCLOSURE BUT SINCE THIS APPEARS TO BE AN ABS ONLY ISSUE AND WE’RE GETTING SUCH GOOD RESULTS FROM PLA THEN THIS MAY NOT BE AN ISSUE IN THE LONG RUN.*

PRINT QUALITY – WE HAD A FEW SAMPLES MADE UP ON THE LEAPFROG BOLT AND WERE PLEASED WITH THE RESULTS*

PRICE – THE COST WAS IN THE RIGHT BALLPARK TO BE ABLE TO MAKE THE BUSINESS CASE FOR THE LEADERSHIP TEAM. Rez Manzoori – BEng(Hons) CEng MRAeS Turbine Sub-System Integration CROCS™ – BOLT PRO ADVANTAGES FOR DESIGN. WHY DID YOU CHOOSE THE BOLT PRO 3D PRINTER?*

THE BOLT IS FITTED WITH A LARGE BUILD VOLUME. LARGE ENOUGH TO CREATE PROTOTYPES THAT CAN BE TESTED FOR IMPROVEMENT.*

IT ALSO CAN PRINT MANY DIFFERENT TYPES OF MATERIALS, INCLUDING FLEXIBLE PLASTIC. IN GENERAL, 3D PRINTING USING FLEXIBLE MATERIAL CAN PROVE TO BE DIFFICULT, BUT THE ADVANCED DIRECT DRIVE OF THE BOLT CONTROLS THE FLOW OF THE FILAMENT EXPERTLY THROUGH THE NOZZLE. WHAT ARE WE USING THE LEAPFROG 3D PRINTERS FOR? For PROTOTYPING, to be able to DEVELOP NEW PRODUCTS QUICKLY. Today we have many different models of Crocs footwear. This achievement has been by thinking of prototyping in a different way using Leapfrog’sBolt 3D Printer.

WHAT IS YOUR GENERAL IMPRESSION OF 3D PRINTING AND THE LEAPFROG BOLT? Enthusiasm for the Bolt has started to become recognized outside of Crocs innovation department with our international colleagues. WE RECOMMEND THIS MACHINE for prototyping purposes in most PROFESSIONALENVIRONMENTS.

Luca Faggin, Europe innovation manager Crocs™ 3D PRINTING HELPS SURGEONS PLAN, PRACTICE PROCEDURES STELLENBOSCH FACULTY OF MEDICINE & HEALTH SCIENCES HOW 3D PRINTING IS USED IN SURGERY? 3D printing is having a major impact on medicine in a number of ways. This is mainly evident in Orthopedic Surgery where doctors use 3D printing to help treat patients musculoskeletal system. 3D scans are taken of patients and using that data, doctors print replica accuratebones of patients.

WHAT ARE THE MODELS USED FOR?*

TO VIEW INJURIES MORE ACCURATELY TO HELP PLAN SURGERY*

TACTILE FEEDBACK FOR DOCTORS*

PRACTICE SURGICAL PROCEDURES BEFORE FULL OPERATION*

TO REVIEW TREATMENT WITH ACCURATE COMPARISONS BETWEEN THE TREATMENTTIME PERIOD

Dr Rudolph Venter, Division of Orthopaedic Surgery, StellenboschUniversity

SEE VIDEO TESTIMONIALTRUSTED BY

PROFESSIONALS

Professionals around the world are using functional 3D printing to drastically improve their product development process in various ways. Most of the global leading companies in engineering, the automobile industry, robotics, architecture, and medical care have integrated 3D printing into their workflows to cut lead times and to bring back control of the process in-house. These range from prototyping parts before mass production, to producing functional parts that can demonstrate how a part will work. To help these companies, Leapfrog 3D Printers designs and produces a range of professional 3D printing solutions that aim to help our customers achieve results faster and produce the highest quality 3D printed parts. __ SEE ALL PROFESSIONSTRUSTED BY

PROFESSIONALS

Professionals around the world are using functional 3D printing to drastically improve their product development process in various ways. Most of the global leading companies in engineering, the automobile industry, robotics, architecture, and medical care have integrated 3D printing into their workflows to cut lead times and to bring back control of the process in-house. These range from prototyping parts before mass production, to producing functional parts that can demonstrate how a part will work. To help these companies, Leapfrog 3D Printers designs and produces a range of professional 3D printing solutions that aim to help our customers achieve results faster and produce the highest quality 3D printed parts. __ SEE ALL PROFESSIONS WHAT THE EXPERTS SAY MAKE MAGAZINE: REVIEW ON BOLT’S SPECS AND 3D PRINTS "The Bolt is a powerful device with industrial mechanics and proved to be easy to use in the test. The dual extrusion mode works well, thanks to the enclosed installation space, the heat output of the extruders (up to 360 degrees Celsius) and the construction platform (up to 90 degrees Celsius), the machine is suitable for a wide range ofmaterials"

__ READ ENTIRE REVIEW REVIEW BY BUSINESS.COM: XEED 3D PRINTER "With a wide choice of materials, very tight precision and a unique dual-extruder design, Leapfrog's Xeed 3D printer is a designer's dream come true." Read more. __ READ ENTIRE REVIEW 3DPRINTR.COM: REVIEWING THE UNIQUE FEATURES OF BOLT A few weeks ago, I received the Leapfrog Bolt for intensive testing. Besides a lot of very positive things I have only a few minor points of criticism. What I enjoyed most were the two independent extruders, the air filter and the good print quality when printing with ABS and many other materials. __ READ ENTIRE REVIEW 3DPRINTING.COM: IN-DEPTH REVIEW ON THE BOLT "Definitely one of the best printers we’ve ever tested. The intuitive interface, massive build volume, closed print chamber and independent dual extruders make this printer a true workhorse that will bring your prints to the next level." __ READ ENTIRE REVIEW Previous NextTRUSTED BY

PRECISION, DURABILITY, CONSISTENCY DISCOVER YOUR 3D PRINTERXCEL

Max print dimensions550 x 500 x 2240 mm

__ See details

BOLT PRO

Max print dimensions300 x 320 x 205 mm

__ See details

XEED 2.0

Max print dimensions280 x 220 x 230 mm

__ See details

NEWSLETTER

Subscribe to our weekly newsletter for useful tips and valuableresources.

First Name

Last Name

Email Address

Leave this field empty if you're human:* __

* __

* __

* Information

* Filaments

* About

* Jobs

* Support

* Press

* Customers

* Resellers

* Terms and conditions * Order and shipment * Leapfrog Privacy Policy * Delivery & return policy� 2020 Leapfrog

Terms of Use

Privacy and Cookie PolicyFIND RESELLERS

* __Buy your Bolt Pro 3D printer nearby * __The lowest shipping costs * __The quickest delivery United States Australia Belgium Brazil China Colombia Czech Republic EMEA Finland France Germany Greece Indonesia Italy Korea, Republic Of Portugal Romania Russian Federation Saudi Arabia Thailand Turkey United Arab Emirates United Kingdom United StatesACCUCODE3D

United States

__ VISIT WEBSITE

B&H PHOTO INC.

United States

__ VISIT WEBSITE SEE ALL RESELLERS Leapfrog contact information in The Netherlands * __ +31 172 503 622 * __ sales@lpfrg.comCONTACT US

PHYSICAL ADDRESS

H. Kamerlingh Onnesweg 10 2408 AW Alphen aan den RijnThe Netherlands

POST OFFICE ADDRESS

PO Box 252

2400 AG Alphen aan den RijnThe Netherlands

Details

Copyright © 2024 ArchiveBay.com. All rights reserved. Terms of Use | Privacy Policy | DMCA | 2021 | Feedback | Advertising | RSS 2.0